Key Takeaways

- The selection of boat flooring impacts the vessel’s durability, safety, and comfort.

- Materials range from durable vinyl to comfortable foam, each with unique benefits.

- Considerations include resistance to elements, ease of maintenance, and suitability.

Are you looking for the best boat flooring? Discover the top choices to enhance your vessel's aesthetics and functionality.

The best boat flooring options include PVC Tiles, Rubber Boat Flooring, Marine Carpet, Foam Boat Flooring, Teak Wood, and EVA Decking. These materials provide durability, comfort, and aesthetic appeal, catering to various needs such as resilience, elegance, and shock absorption.

As a seasoned boating enthusiast, I've seen firsthand how the right flooring transforms a vessel. In my experience, the options don't just enhance the look; they revolutionize your boat's functionality. With that in mind, choosing the right flooring is a game-changer for any seafarer.

Best Boat Flooring Options

Choosing the best boat flooring is crucial not only for maintaining your vessel's durability but also for ensuring the safety and comfort of everyone on board. Whether you're a seasoned sailor or new to boating, understanding the vast array of flooring options—from PVC and rubber to marine carpets and foam—can help transform your marine experience.

Vinyl marine flooring options vary significantly in their installation, cost, maintenance, and aesthetic appeal. Durable materials like vinyl or aluminum boats are favored for their resilience and easy cleaning, while options like foam boat flooring offer comfort underfoot and excellent slip resistance, crucial for safety when the deck gets wet.

Your choice will also depend on the specific needs of your boat; fishing vessels might benefit from waterproof and blood-resistant surfaces, while luxury yachts may prioritize stylish designs and plush textures.

Here is a comparison table of different boat flooring options:

1. PVC Flooring Tiles

Art3d Textures PVC Floor Tiles

PVC flooring tiles are a versatile and practical choice for your boat's deck. They offer a balance of durability and style, making them a popular option among boat owners.

PVC Flooring Tiles stand out as a versatile and durable option in the realm of boat flooring. These tiles, known for their robustness and resistance to the harsh marine environment, offer an ideal balance between practicality and aesthetic appeal. The ease of installation and maintenance makes PVC tiles a favorite among boat owners, particularly those who seek a cost-effective yet stylish solution.

The material's inherent water resistance and anti-slip properties ensure safety on deck. At the same time, the variety of designs and colors available allows for personalization of the boat's interior to reflect the owner's style.

Materials Needed

- Measuring tape

- Utility knife

- PVC compatible adhesive

- Notched trowel

- Roller

Best Options

- Ktaxon Interlocking PVC Floor Tiles

- TrafficMaster Allure PVC Flooring

- Art3d Textures PVC Floor Tiles

Application Steps

- Measure the area where you'll be laying the tiles.

- Cut the PVC tiles to fit using a utility knife.

- Apply adhesive to the subfloor with a trowel.

- Lay the tiles down, starting from the center, and work your way outwards.

- Roll over the tiles with a roller to ensure proper adhesion.

Pros

- Highly durable and able to withstand heavy foot traffic

- PVC tiles protect against spills and are unaffected by moisture

- Choose a style that complements your boat's interior design

Cons

- They have a firmer feel, which may be less comfortable for standing for long periods

- Requires precision cutting and fitting, especially around corners and edges

2. Rubber Boat Flooring

KXKZREN Boat Flooring

Rubber marine flooring is a practical and durable option for boat owners who prioritize safety and longevity. It's recognized for its non-skid properties, robustness against the elements, and ability to withstand heavy foot traffic.

Materials Needed

- Rubber flooring rolls or tiles

- Adhesive suitable for marine environments

- A utility knife for cutting the material

- A roller to ensure firm adhesion

- Cleaning supplies for surface preparation

Best Options

Application Steps

- Clean the boat floor thoroughly to remove any grime or residue.

- Measure the area and cut the rubber flooring to fit.

- Apply a marine-grade adhesive to the boat floor.

- Lay the rubber flooring down, pressing firmly.

- Use a roller to smooth out any air bubbles and ensure a secure bond.

Pros

- Stands up to heavy use and harsh marine conditions

- Offers excellent slip resistance for safety

- It does not absorb water, preventing mold and mildew growth

- Simply hose down or mop to remove dirt and spills

Cons

- It may not offer the same upscale look as other flooring options

- It can become hot under direct sun exposure, uncomfortable for bare feet

- Usually heavier than other flooring types, which may affect the boat's performance

3. Marine Carpet Flooring

SeaDek Marine-Grade Outdoor Carpet

Marine carpet flooring offers a blend of comfort and durability for boat owners. Specifically designed to withstand elements like water and UV-resistant, it comes in diverse colors and is engineered to resist mold, mildew, and moisture absorption.

Materials Needed

- Marine carpet: Choose from a variety of colors and patterns to match your style.

- Marine carpet adhesive: A waterproof glue to ensure a secure installation.

- Rollers or brushes: To spread the adhesive evenly.

- Cutting tools: A sharp knife or scissors for trimming the boat carpet.

- Heavy-duty tape measure: For accurate sizing.

- Cleaning supplies: Including a vacuum and damp cloth for surface preparation.

Best Options

- Better Boat Marine-Grade Carpet

- SeaDek Marine-Grade Outdoor Carpet

- Attwood Marine-Grade Indoor/Outdoor Carpet

Application Steps

Preparation:

- Clean the surface where the carpet will be installed, ensuring it's free of debris and moisture.

- Measure the area accurately to cut the carpet accordingly.

Installation:

- Lay the marine carpet out and allow it to acclimate to avoid wrinkles.

- Apply adhesive using rollers or brushes.

- Place the carpet on the surface neatly and press it down firmly.

Finishing:

- Trim any excess carpet for a perfect fit.

- Use a roller to eliminate air pockets and ensure full adherence to the boat floor.

Pros

- Soft surface that feels good even when you're barefoot

- Wide selection of colors to match your boat's interior design

- Manufactured to handle wet conditions without absorbing water

- Treated fabrics help prevent the growth of mold and mildew

Cons

- Requires proper maintenance to prevent odor and deterioration

- Despite UV resistance, long periods of sun exposure can degrade the carpet

- When soaked, it might be challenging to fully dry out the carpet

- Can collect fish blood, bait, and other debris that requires cleaning

4. Foam Boat Flooring

Nautolex Nitrile Foam Flooring

Foam boat flooring, often made of ethylene-vinyl acetate (EVA), is a practical and aesthetically appealing choice for boat owners seeking a combination of comfort and durability. Specifically designed for marine environments, EVA foam is known for its slip-resistant surface and UV resistance.

Materials Needed

- EVA foam flooring sheets

- Adhesive (marine grade)

- Utility knife or scissors

- Straight edge or ruler

- Cleaning supplies (alcohol wipes or a cleaning solution)

- Masking tape

- Caulk gun (optional for adhesive cartridges)

Best Options

Application Steps

- Prepare the Surface: Clean the boat floor thoroughly to remove any debris, oils, or existing adhesives. Ensure the surface is dry before proceeding.

- Measure and Cut: Lay the EVA foam sheets on the deck, mark the appropriate measurements with a marker and cut them to size using a utility knife or scissors.

- Dry Fit: Place the cut sections onto the floor to ensure they fit properly before applying any adhesive.

- Apply Adhesive: Apply the marine-grade adhesive to the back of the foam sections following the manufacturer's instructions.

- Install the Flooring: Carefully position the foam sections on the boat floor. Press firmly to secure the flooring and eliminate air bubbles.

- Seal Edges: (Optional) Use a caulk gun to apply a sealant around the edges for additional waterproofing and durability.

Pros

- EVA foam provides a cushioned surface that's gentle on your wet feet

- The non-slip texture improves safety by reducing slips and falls

- EVA foam is UV stable, protecting it from sun damage and fading

- Available in various colors and patterns to match your boat's style

- Easy to clean with water and mild soap, resisting stains, fish blood, and other debris

Cons

- Darker colors can absorb heat and feel warm to the touch

- While durable, sharp objects can gouge the foam surface

- It may not last as long as harder flooring types with proper maintenance

- It requires accurate cutting and fitting, or it can look unprofessional

5. Aluminum Boat Flooring

SeaDek Anti-Fatigue Aluminum Flooring

When considering aluminum boat flooring, you're looking at a highly durable option that stands up well to water exposure and is renowned for its longevity. It's designed to withstand the rigors of aquatic environments, making it an ideal choice for your boating needs.

Materials Needed

- Aluminum flooring sheets: Typically marine-grade to resist corrosion.

- Tools: Measuring tape, metal cutter, drill, and screws for installation.

- Sealant: Waterproof sealant to protect against water seepage.

Best Options

- SeaDek Anti-Fatigue Aluminum Flooring

- Treadmaster Aluminum Flooring

- Better Boat Diamond Plate Aluminum Flooring

Application Steps

- Measure: Accurately measure the boat floor to determine the amount of material needed.

- Cut: Trim the aluminum flooring sheets to fit the boat's contours.

- Fit and Seal: Position the cut sheets on the floor, seal the edges, and screw down.

Pros

- Aluminum flooring is known for unmatched durability

- It does not absorb water, ensuring that your floor stays dry

- Offers UV stability, preventing damage from prolonged sun exposure

- Requires minimal upkeep compared to other types of flooring

Cons

- It can become hot to touch under direct sunlight

- Less comfortable for standing for long periods vs. soft foam boat flooring

- While generally resistant, it can corrode in saltwater if not properly treated

6. Drainage Tiles

Blomus Drainage Floor Tiles

When it comes to maintaining a clean and safe environment on your boat, drainage tiles are an excellent solution. They are designed to allow water, mud, and grime to flow through easily, ensuring a non-skid finish that keeps you secure underfoot in wet conditions.

Materials Needed

- Drainage tiles

- Measuring tape

- Utility knife (if trimming is required)

Best Options

- Blomus Drainage Floor Tiles

- DeckWise Ipe Clip Hidden Fastener Tiles

- DriDek Interlocking Drainage Tiles

Application Steps

- Measure your boat floor area to determine the number of drainage tiles needed.

- Lay tiles starting from one side of the floor, working your way to the other.

- If necessary, trim the tiles to fit using a utility knife.

Pros

- Tiles offer a non-slip surface for safety

- Easy to install; no professional help needed

- Resistant to UV damage and weather conditions

- Optimal for a fishing boat; liquids and debris easily flow through

Cons

- It can be more expensive than other flooring options

- It may be uncomfortable standing for long periods

- Require proper maintenance to prevent buildup under the tile

7. Marine Vinyl Flooring

Marine vinyl flooring is a top choice for boat owners looking to outfit their crafts with a durable and aesthetically pleasing surface. It's a practical solution that combines water-good sound resistance and low maintenance with a stylish finish.

Materials Needed

- Marine vinyl flooring

- Adhesive suitable for marine environments

- Notched trowel

- Utility knife

- 75 lb. floor roller

- Acetone or another suitable solvent for cleaning

- Mineral spirits for adhesive cleanup

- Tape measure

- Straightedge

Best Options

Application Steps

- Preparation: Clean the subfloor thoroughly, ensuring it's dry and free from any debris.

- Measurements: Measure the area to cover and cut the vinyl accordingly, allowing a bit extra for trimming.

- Adhesive Application: Spread adhesive over the subfloor using the notched trowel.

- Laying the Flooring: Carefully lay the vinyl onto the adhesive, avoiding air bubbles and wrinkles.

- Sealing: Roll the floor with a 75 lb. roller to ensure a secure bond.

- Trimming: Trim the excess material around the edges.

- Cleanup: Use mineral spirits to clean any residual adhesive before it dries.

Pros

- Great at resisting stains, which helps retain the boat's interior design intact

- Offers unmatched water resistance, a must for marine environments

- Known for its durability and ability to withstand heavy foot traffic

- Available in various patterns and colors, enhancing the overall aesthetic appeal

Cons

- It may have a harder feel underfoot, providing less comfort than softer options

- It can retain heat, which may be uncomfortable in hot weather

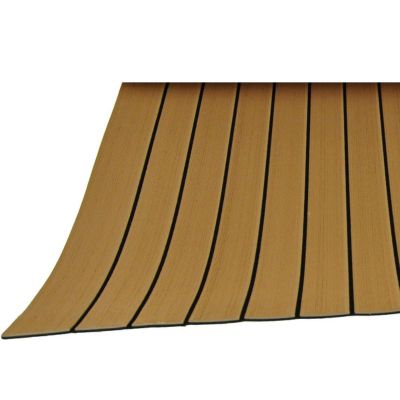

8. Teak Wood Flooring

SeaDek Teak Flooring

When outfitting a boat, selecting the right boat flooring is critical for both practicality and aesthetics. Teak wood flooring is a high-end option that delivers durability and a classic look that never goes out of style.

Materials Needed

- Teak wood planks or tiles

- Marine adhesive

- Sealant

- Sandpaper or sander

- Cleaning supplies

- Saw (for cutting planks)

Best Options

Application Steps

- Preparation: Clean the subfloor thoroughly and sand any high points.

- Cutting to Fit: Measure and cut the teak planks to fit the allocated space.

- Gluing Down: Apply marine adhesive to the subfloor and carefully lay down the teak planks.

- Sealing: Once the floor is laid out, seal the wood to protect against water and UV damage.

Pros

- Adds elegance to any boat's interior design

- Known for its long-lasting quality on fishing boats and yachts alike

- Teak naturally repels water, helping to prevent rot

- With proper maintenance, the teak withstands sun exposure without significant fading

Cons

- Teak is often more expensive compared to other boat flooring options

- Requires regular cleaning and resealing to preserve its looks

- It can add significant weight to ski boats, affecting performance

9. EVA (Ethylene Vinyl Acetate) Decking

When selecting the best boat flooring, Ethylene Vinyl Acetate (EVA) decking is a prominent choice among boat owners for its balance of comfort and durability. It offers a practical and aesthetically pleasing option for marine flooring, giving a touch of style to any boat floor.

Materials Needed

- EVA foam sheets or custom-cut panels

- Adhesive compatible with EVA foam

- Utility knife or a sharp cutting tool

- Straight edge or ruler

- Cleaning solvents

- Masking tape

- Caulking gun (for adhesive application)

Best Options

Application Steps

- Surface Preparation: Ensure the boat floor area is clean, dry, and free from any debris.

- Measuring: Accurately measure the areas to be covered.

- Cutting: Use a sharp utility knife to cut the EVA material to fit the specified measurements.

- Dry Fitting: Place the cut pieces onto the installation area to ensure a proper fit.

- Applying Adhesive: Apply the recommended adhesive to the floor area or the back of the EVA foam, then carefully lay the EVA material in position.

- Securing in Place: Press down firmly on the EVA decking, allowing for proper adhesive bonding.

Pros

- Offers excellent traction even when wet, enhancing safety

- The soft material provides anti-fungal coating properties

- It does not absorb water, reducing the risk of mildew and mold growth

- Many EVA products are treated for UV stability

Cons

- Darker colors of EVA foam can get quite hot under direct sunlight

- While durable, it may suffer cuts and scrapes from sharp objects more easily

- It can be susceptible to stains from fish blood and other best materials

- Quality EVA decking may come at a premium price

10. Cork Flooring

SwissTrax Cork Flooring

Cork flooring has become a sought-after boat flooring option due to its durability, water resistance, and comfort. Its aesthetically pleasing appearance can complement a boat's interior design while also offering sound-dampening properties and mildew resistance, making it a practical choice for marine flooring.

Materials Needed

- High-quality marine cork flooring tiles or sheets

- Adhesive suitable for marine environments

- A utility knife or saw for cutting cork to size

- A notched trowel for spreading adhesive

- A roller to press down cork tiles or sheets

- Clean cloths and mild detergent for surface preparation

Best Options

Application Steps

- Surface Preparation: Clean the existing floor to remove dirt, oil, and any previous flooring material residues. The subfloor must be dry and level.

- Cutting to Size: Measure the boat floor area and cut the cork material accordingly, allowing for some margin at the edges.

- Applying Adhesive: Use the notched trowel to spread the adhesive evenly on the subfloor. Work in sections to prevent the adhesive from drying out before the cork is placed.

- Laying Cork: Place the cork tiles or sheets onto the adhesive, pressing firmly. Roll over the surface with a roller to eliminate air bubbles.

- Drying: Allow the adhesive to cure as recommended by the manufacturer before using the area.

Pros

- Cork is soft underfoot, reducing fatigue from long periods of standing

- It provides a natural and inviting look, adding warmth to the boat's interior

- It helps to reduce noise levels, which is beneficial on noisy fishing boats or busy yachts

- Natural insulator against both temperature and sound

- Cork is a renewable, sustainable material

- Resistant to mold and mildew, contributing to better air quality

Cons

- It can be pricier than other boat flooring options like vinyl or marine carpet.

- Susceptible to UV damage over time unless treated with a UV-stable finish.

- Requires regular maintenance to retain its water-resistant properties.

- It may absorb water if not properly sealed, leading to potential damage.

11. Bamboo Marine Flooring

When considering the best boat flooring options, bamboo stands out for its unique combination of aesthetics and resilience. It offers a finely woven, UV-resistant option that's both stylish and durable, making it suitable for an array of boating needs.

Materials Needed

- High-quality bamboo marine flooring rolls

- Marine-grade adhesive

- Trowel or spreader for the adhesive

- Utility knife for trimming

- Heavy roller to ensure solid bonding

Best Options

Application Steps

- Preparation: Ensure the boat floor is clean, dry, and free of debris.

- Measuring: Accurately measure the area where the flooring will be applied.

- Cutting: Use a utility knife to cut the bamboo flooring to size.

- Applying Adhesive: Spread the marine-grade adhesive evenly on the subfloor.

- Laying Flooring: Carefully place the bamboo material onto the adhesive-layered floor.

- Bonding: Use a heavy roller to press down the flooring, ensuring a strong bond.

Pros

- Imparts an elegant look to the boat's interior design

- It offers unmatched durability and is suitable for long periods

- Requires minimal upkeep and is resistant to sun exposure

- Engineered for high water resistance and can withstand wet conditions

Cons

- It is more expensive than some other boat flooring options

- It can be challenging to install without professional help

- Although UV stable, prolonged exposure may lead to some wear

- It can retain fish blood and other debris if not properly cleaned

12. Synthetic Grass Decking

When considering marine flooring options, synthetic grass decking stands out as a versatile choice for boat owners. It blends aesthetics with functionality, offering a unique finish that mimics natural turf on the sea.

Materials Needed

- High-quality synthetic grass suitable for marine use

- A marine-grade adhesive to ensure a secure fit

- A utility knife for cutting the grass to the boat's floor dimensions

- A notched trowel to spread the adhesive evenly

- A heavy roller to ensure good contact between the grass and the adhesive

Best Options

Application Steps

- Measurement: Precisely measure the area where the synthetic grass will be placed.

- Cutting: Use the utility knife to cut the synthetic grass to the required dimensions.

- Adhesive Application: Apply a marine-grade adhesive to the boat floor with the notched trowel.

- Placement: Lay the synthetic grass carefully over the adhesive.

- Securing: Press the grass into place with a heavy roller to eliminate air pockets and ensure strong adhesion.

Pros

- Mimics the look of natural grass, enhancing the boat's visual appeal

- Soft underfoot, providing a comfortable surface for standing or walking

- It offers a non-skid surface, reducing the likelihood of slips and falls

- Resistant to sun exposure, UV damage, and wear from foot traffic

Cons

- Can trap dirt, grime, and fish blood, requiring regular cleaning

- May retain heat, potentially becoming uncomfortable for bare feet in hot weather

- Initially, it can be more expensive than traditional boat flooring options

- If not properly selected or installed, it may absorb water and take longer to dry

13. Polyurethane-Coated Flooring

When considering the best boat flooring, polyurethane-coated options offer a durable, water-resistant solution perfect for marine environments. This coating significantly enhances the life of floors by providing protection against the elements and heavy traffic.

Materials Needed

- Polyurethane coating

- Sandpaper or sanding machine

- Brush or roller

- Cleaning solvent

- Tape for masking areas

- Protective gear (gloves, mask)

Best Options

Application Steps

- Preparation: Clean the surface thoroughly and let it dry. Sand the area for better adhesion.

- Application: Apply polyurethane using a brush or roller over the boat floor, ensuring even coverage.

- Curing: Allow the floor to dry and cure as per the product instructions before using the area.

Pros

- Highly durable against scratches and dents

- Protects from water and moisture damage

- Offers protection from sun exposure, reducing UV damage

- Adds a glossy finish that can enhance the boat's interior design

Cons

- Requires significant surface prep for best results

- It might need reapplication over time to maintain effectiveness

- It could be more expensive than other boat flooring options

14. Composite Decking

When outfitting a boat with new flooring, composite decking emerges as an innovative alternative renowned for its robustness and low maintenance requirements. This type of marine flooring is a fusion of different materials, including PVC and other synthetic elements, often mimicking the fine appearance of traditional woods, like teak.

Materials Needed

- Composite deck boards

- Stainless steel screws

- Drill and appropriate drill bits

- Saw for trimming and shaping boards

- Measuring tape

- Adhesive recommended by the decking manufacturer

- Safety equipment (gloves, glasses)

Best Options

Application Steps

- Preparation: Measure the boat's deck area to determine how much material you will need.

- Cutting: Trim the composite boards to fit the designated space on your boat, allowing for expansion gaps.

- Fitting: Lay the deck boards, fastening them with screws or the recommended adhesive.

- Finishing: Install edging pieces, if provided, to give the decking a neat and finished look.

Pros

- Exceptional resilience against wear and tear

- Requires minimal upkeep, unlike traditional wood decking

- It provides a high-quality finish akin to real wood

- Usually non-porous, which prevents water absorption

- Often designed with textures to reduce slipping

Cons

- It tends to be more expensive than other boat flooring options

- May become hot under direct sun exposure, potentially uncomfortable for bare feet

- It can be more complex to install than simpler flooring options

15. Acrylic-impregnated Wood Flooring

When it comes to high-end marine flooring, acrylic-impregnated wood flooring presents an elegant and robust option. This type of flooring is infused with acrylic resin, which gives it superior durability and moisture resistance, making it suitable for boat flooring where conditions can be harsh.

Materials Needed

- Acrylic-impregnated wood planks

- Adhesive compatible with marine use

- Subfloor (marine-grade plywood)

- Saw for cutting wood

- Notched trowel

- Heavy-duty roller

Best Options

Application Steps

- Prepare the subfloor by ensuring it is clean, dry, and debris-free.

- Spread the adhesive evenly on the subfloor using a notched trowel.

- Lay the acrylic-impregnated wood planks onto the adhesive, ensuring a tight fit.

- Use a heavy-duty roller to ensure proper adhesion of the planks to the subfloor.

- Allow the floor to cure based on the adhesive manufacturer's recommended time.

Pros

- Grain patterns exhibit elegance and class

- It offers excellent protection against moisture

- Can withstand heavy foot traffic and furniture weight

- Retains its appearance over time with less fading

Cons

- More expensive than other boat flooring options

- Requires regular cleaning to maintain its high-quality finish

- Less forgiving on the feet compared to foam or vinyl flooring

- Generally requires professional installation

Psychology of Color and Texture in Boat Flooring

This section highlights how the selection of boat flooring goes beyond mere functionality, delving into the psychological and aesthetic impact it has on the boating experience.

Impact of Colors on Mood and Atmosphere Onboard

Colors play a vital role in setting the mood on a boat. Light, airy hues like blues and greens evoke a sense of calmness, mirroring the sea and sky, while warmer tones can create a cozy, inviting environment. The choice of color in flooring can significantly influence the overall ambiance of the boat.

Texture's Role in Comfort and Safety

The texture of boat flooring is not just about physical comfort; it's about safety, too. Rough textures provide better grip in wet conditions, which is crucial for preventing slips and falls. Conversely, softer textures offer comfort for barefoot relaxation, enhancing the leisure experience on board.

Choosing the Right Combination for Activities

Different boating activities call for different flooring choices. For fishing and active sports, durable and slip-resistant surfaces are paramount. For luxury cruising, softer, more aesthetically pleasing textures and colors enhance the experience. Balancing functionality with style is key.

Case Studies of Successful Implementations

Examining real-life examples where color and texture combinations have been successfully implemented can provide valuable insights. For instance, a luxury yacht uses teak with soft beige tones for elegance, or a sport fishing boat opts for dark, textured rubber flooring for practicality and durability.